FIP (Form-In-Place) Gasketing

FIP: Form-In-Place

What is FIP (Form-In-Place) Gasketing?

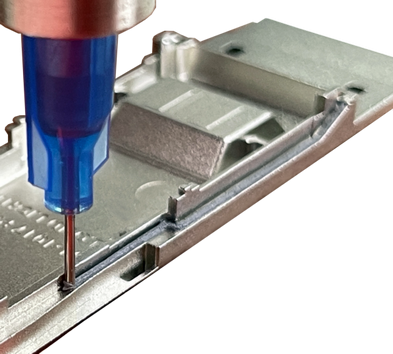

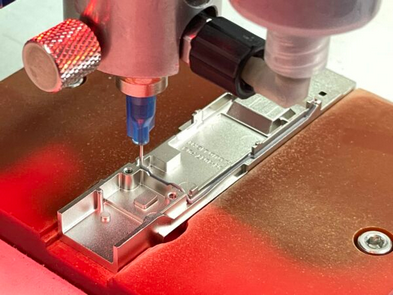

Form-in-place (FIP) gasketing is a sealing technique where a liquid gasket material is dispensed onto a component and then cured to form a solid seal. FIP gaskets are dispensed using automated dispensing equipment, typically a CNC machine, which allows for precise control over the bead size and placement.

Conformability: FIP gaskets can conform to uneven surfaces, providing a better sealing than pre-formed gaskets.

Versatility: FIP gaskets can be dispensed in a wide variety of shapes and sizes, making them suitable for a wide range of applications.

Elimination of inventory: Since FIP gaskets are dispensed on-demand, there is no need to stock a variety of pre-formed gaskets.

Improved assembly efficiency: FIP gaskets can be applied quickly and easily during the assembly process.

EMI/RFI shielding: FIP gaskets can be formulated to be electrically conductive, which helps to block electromagnetic interference (EMI) and radio frequency interference (RFI).

Environmental sealing: FIP gaskets can be used to seal out dust, moisture, and other contaminants.

Adhesive applications: FIP gaskets can be used to bond components together.

Evercast has performed thousands of FIP process for our customers, especially the optical transceiver module, with abundant experiences. Please contact our Sales Team for further information.