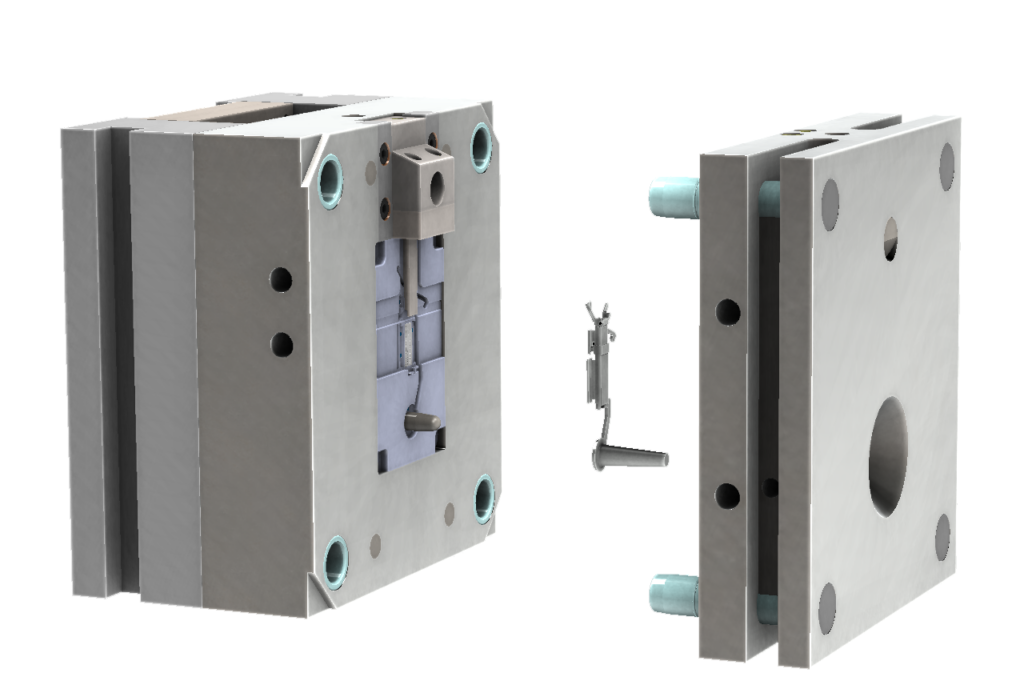

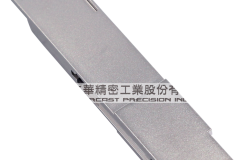

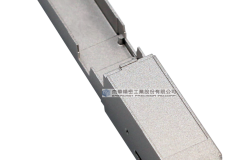

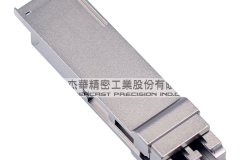

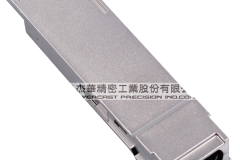

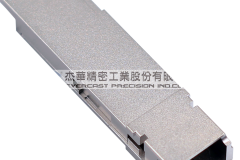

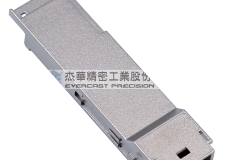

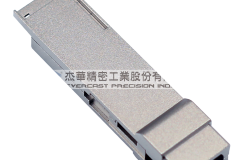

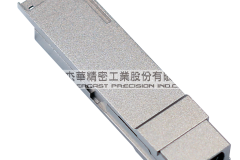

Zinc Diecasting

Evercast have more than 25 years of experiences manufacturing zinc alloy diecasting tooling and parts. There are many different parts we’ve made for our customers around the world. From regular standard hardware to precise optical purpose mechanical products, thousands of millions of pieces were produced and delivered. To learn more about what we have made for our customers, please consult with our Sales Team. Thanks.

Capability

- Diecasting 6,000~12,000 shots/day/machine(varied by products)

- Projection Area Max. 200cm2

- Part Thickness Min. 0.30mm

- Tolerance Min. +/-0.025mm; Nominal. +/-0.05mm

- Thickness 0.60mm(varied by structures, partially 0.30mm)

- Material Zamak#2, #3 & #5 (ASTM B86 AC43A, AG40A & AC41A)

- CNC Machined Samples (Mockup) 10~14 working days

- New Tooling L/T 14~30 working days (varied by products)

- Delivery 10~30 calendar days (varied by products)

Examples

- Bidi, SFP, XFP, CXP, QSFP, QSFP-DD, OSFP, CFPx, SFP-DD, Micro-SFP(µSFP) series housings

- ELSFP (External Laser Small Form-Factor Pluggable) housings for CPO switches

- Optical connector active or passive components (good for EMI shielding)

- Mini-SAS series housings

- DVI/HDMI Connector Housing

- HDMI AOC Connector Housing

- Hinges & stands for Laptop, LCD monitor, Cellphone and Hand-held Devices

- Water-proof connectors

- Mechanical parts for switch & server racks, e.g., guide pins or push bars

- Lens holder for pocket portable projector

Product Showcase