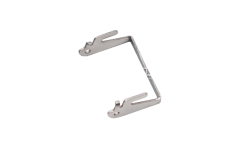

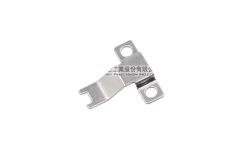

Stamping

Sheet metal stamping is a manufacturing process that uses a die to create a three-dimensional shape from a sheet of metal. The die is a metal form that has the desired shape of the finished product. The sheet metal is placed on the die and then a press is used to force the metal into the shape of the die.

Sheet metal stamping is a versatile process that can be used to create a wide variety of products, including:

- Automotive parts

- Appliances

- Electronics

- Packaging

- Hardware

The advantages of sheet metal stamping include:

- High production rates

- Precise dimensional tolerances

- Complex shapes can be created

- Low cost per part

The disadvantages of sheet metal stamping include:

- High tooling costs

- Complex dies can be difficult to design and manufacture

- The process can be noisy and dusty

Overall, sheet metal stamping is a versatile and efficient manufacturing process that can be used to create a wide variety of products.

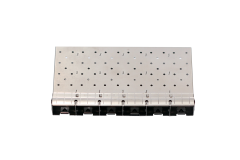

Sheet metal fabrication is the process of using mechanical means to bend, cut, form, and otherwise process sheet metal. Sheet metal fabrication is a common method of manufacturing a variety of products, including automotive parts, electronics, appliances, and packaging.

There are many different methods of sheet metal fabrication, each with its own advantages and disadvantages. The most common methods of sheet metal fabrication include:

- Cutting: Using scissors or a shear to cut the sheet metal into the desired shape.

- Bending: Using a die to bend the sheet metal into the desired shape.

- Stretching: Using a stretcher to stretch the sheet metal into the desired shape.

- Riveting: Using rivets to join the sheet metal together.

- Welding: Using a welding gun to weld the sheet metal together.

Sheet metal fabrication is a versatile process that can be used to create a variety of products. Sheet metal fabrication has the following advantages:

- Cost-effectiveness: Sheet metal fabrication is typically more cost-effective than other methods of fabrication.

- Speed: Sheet metal fabrication can quickly and efficiently produce large quantities of products.

- Precision: Sheet metal fabrication can produce precise products.

- Complexity: Sheet metal fabrication can be used to create complex products.

Sheet metal fabrication has the following disadvantages:

- Material limitations: Sheet metal fabrication can only be used with sheet metal.

- Waste: Sheet metal fabrication produces waste, which can increase costs.

- Noise: Sheet metal fabrication may produce noise.

- Safety: Sheet metal fabrication may be dangerous, so safety precautions should be taken.