Mockup

Mockup samples are indeed a common and efficient method for obtaining prototype samples quickly. They allow engineers to inspect and imitate the products before investing in actual mold or tooling cutting. This saves time, money, and prevents potential failures resulting from possible incorrect mechanical design. At Evercast, there are two types of mockup samples available, primarily differentiated by the material used.

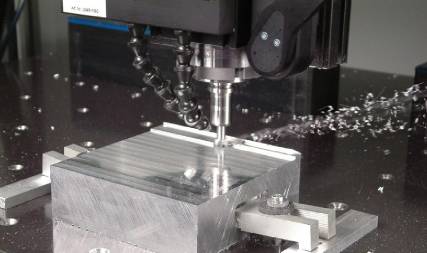

One type is made from aluminum plate or block (usually A6061). These mockup samples offer a perfect surface finish and machining accuracy. They are ideal for achieving precise dimensions and replicating the intended design details.

The other type of mockup sample is made from remelted zinc or aluminum alloy ingots, which are hand-poured to create a block. These hand-poured blocks may have a lower density and a rougher surface compared to the the aluminum mockups. However, they provide engineers with a near-to-shape outlook and the exact weight of the real cast parts, except for variations in density and surface conditions, which might cause certain porosities or air entrapments. Then the CNC machining may expose the defects inevitably. However, this type of mockup sample allows engineers to evaluate the visual appearance and exact weight of the parts without having to wait for the completion of the diecast tooling.

It’s important to note that while the aluminum mockup samples offer superior surface finish and machining accuracy, the hand-poured mockup samples provide a closer representation of the final cast parts in terms of shape and weight. The choice between these two types of mockup samples depends on the specific requirements of the engineering evaluation process.