Machining

Diecasting parts usually involve different types of post machining processes such as drilling, tapping, sand/bead blasting, … etc. In Evercast, we regularly perform various post machining processes for different requirements from the customers.

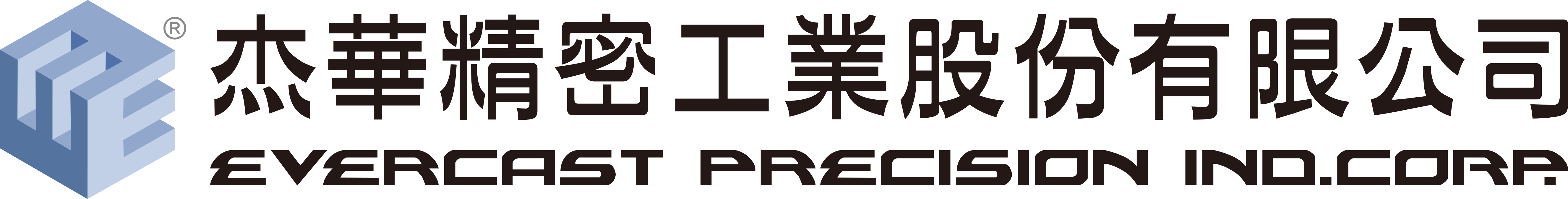

Form-In-Place Gasket

Form-in-Place (FIP) gasketing is a sealing process used in various industries, including automotive, electronics, and manufacturing, to create custom gaskets or seals directly on the mating surfaces of components. This method is particularly useful when standard pre-cut gaskets or seals are not suitable due to irregularly shaped or unique geometries.

Programmable automatic FIP machine lays gasket on the die casting parts with controllable dimensions which results in a better sealability or EMI protection.

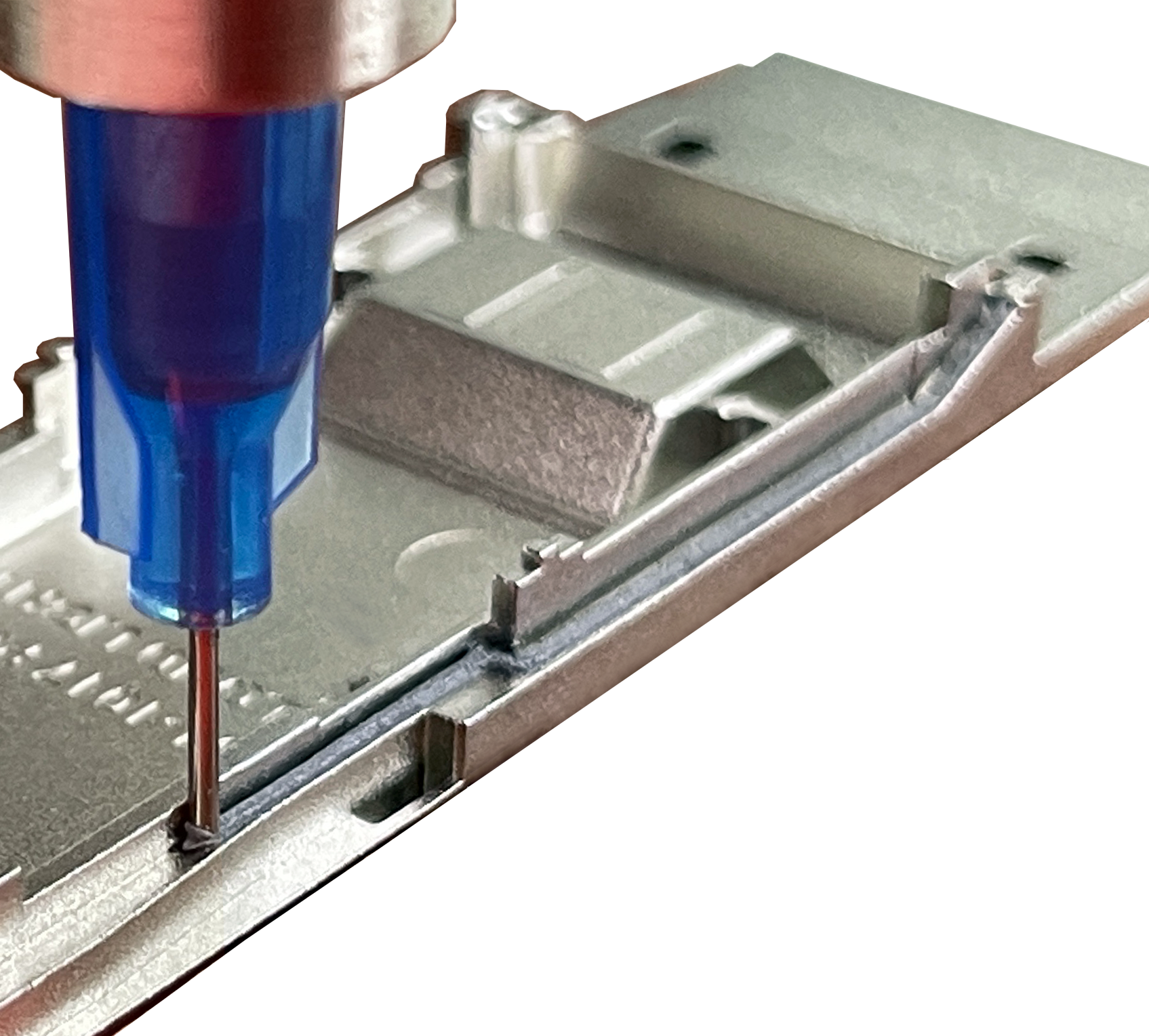

Sand Blasting

Sandblasting, also known as abrasive blasting or media blasting, is a process used to clean, etch, or surface finish a variety of materials through the application of abrasive materials propelled at high speeds and forcibly directed against the target surface using compressed air or other pressurized gases. Common abrasive materials include sand, aluminum oxide, silicon carbide, glass beads, steel grit, and plastic beads. The selection is based on factors such as the material being treated, the desired surface finish, and the level of abrasiveness required.

Sandblasting is commonly used in industries such as manufacturing, construction, automotive, aerospace, and art restoration for various purposes, including cleaning, texturing, and removing surface contaminants such as debris, burrs or flashes with various type of grits.

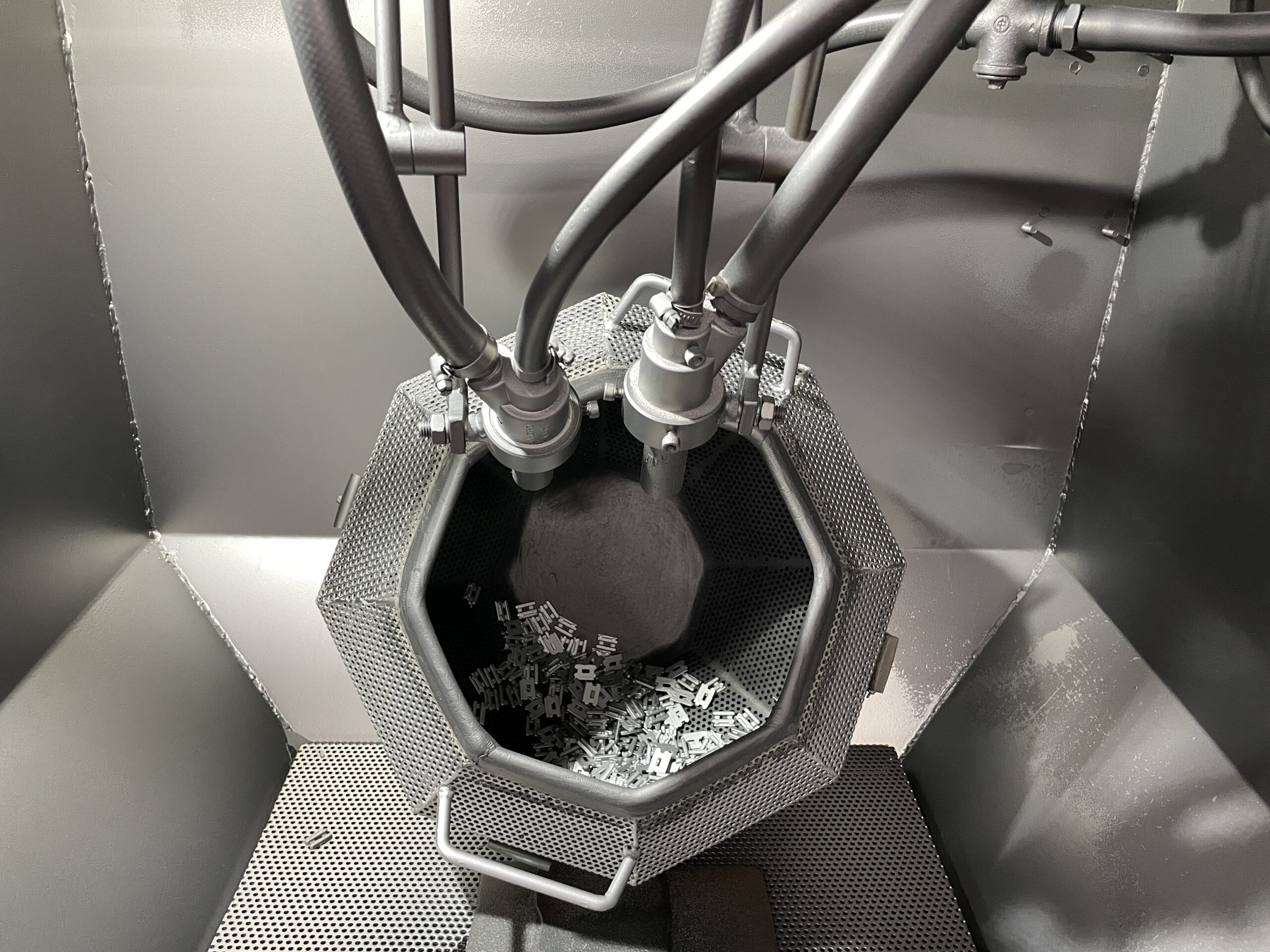

Tapping

Tapping, in the context of machining and metalworking, refers to the process of creating internal threads (helical ridges) inside a hole or cylindrical opening in a workpiece. These threads allow for screws, bolts, or other threaded fasteners to be inserted and securely held in place. Tapping is a fundamental and commonly used technique in manufacturing, construction, and various other industries where threaded connections are required.

Tapping can be performed manually or with an automated tapping machine, CNC machining centers, or other specialized equipment. Tapping is a critical process in the production of components and assemblies where threaded connections are essential.

Single or Multi-spindle tapping machines for making threads on cast parts are available in Evercast.

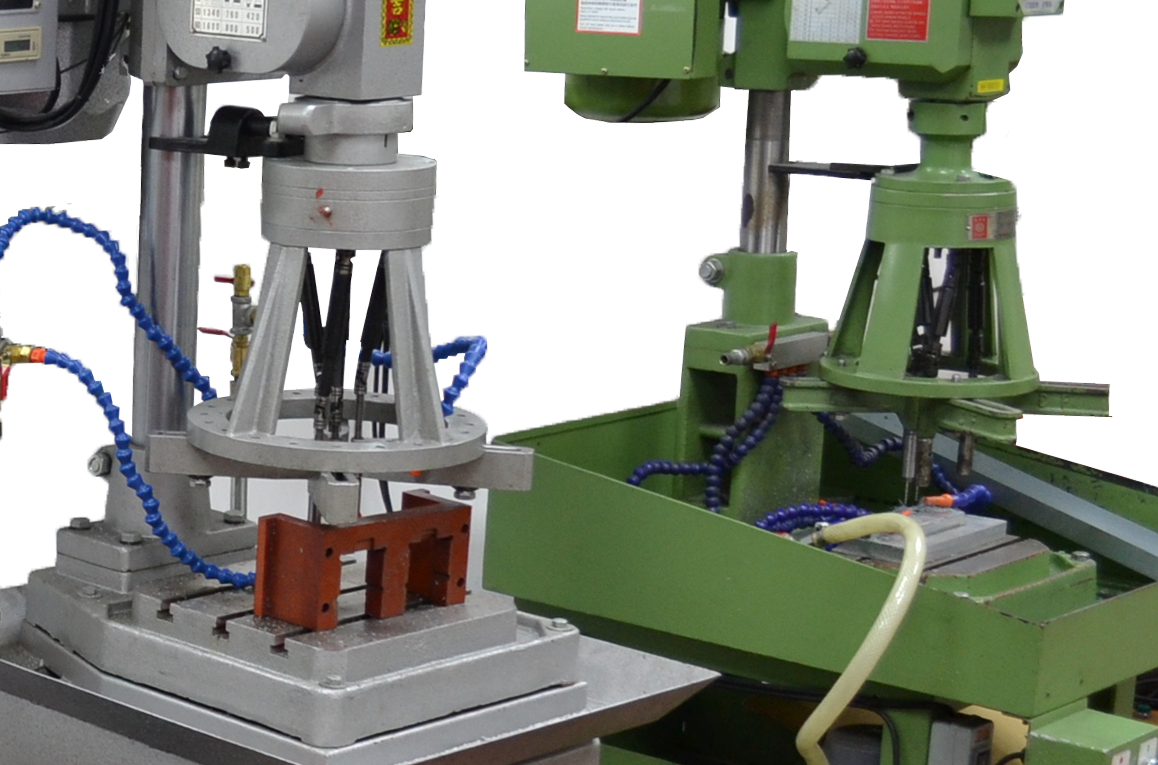

Drilling

Drilling is a machining process used to create cylindrical holes in various materials, including metal, wood, plastic, and composites. It is one of the fundamental and widely used machining operations. The drilled holes can serve various purposes, including accommodating fasteners, guiding mechanical components, providing access for wires or fluids, and more.

Drilling can be performed using various types of drilling machines, including bench drills, pillar drills, radial drills, and CNC machining centers for more precise and automated drilling operations.

Single or Multi-spindle drilling to get blind or through holes on cast parts.

Auto Deburring

Deburring refers to the process of removing burrs from machined or fabricated components using hand tools or automated machinery and processes.

Burrs are unwanted raised edges or irregularities left on the edges or surfaces of workpieces after machining, cutting, or other manufacturing operations. Deburring is essential to improve the quality, functionality, and safety of the finished parts, as burrs can cause assembly problems, reduce performance, and even pose safety hazards.

Deburring at Evercast is performed by both manual and automated machine to remove different sizes of burrs or flashes on cast parts.

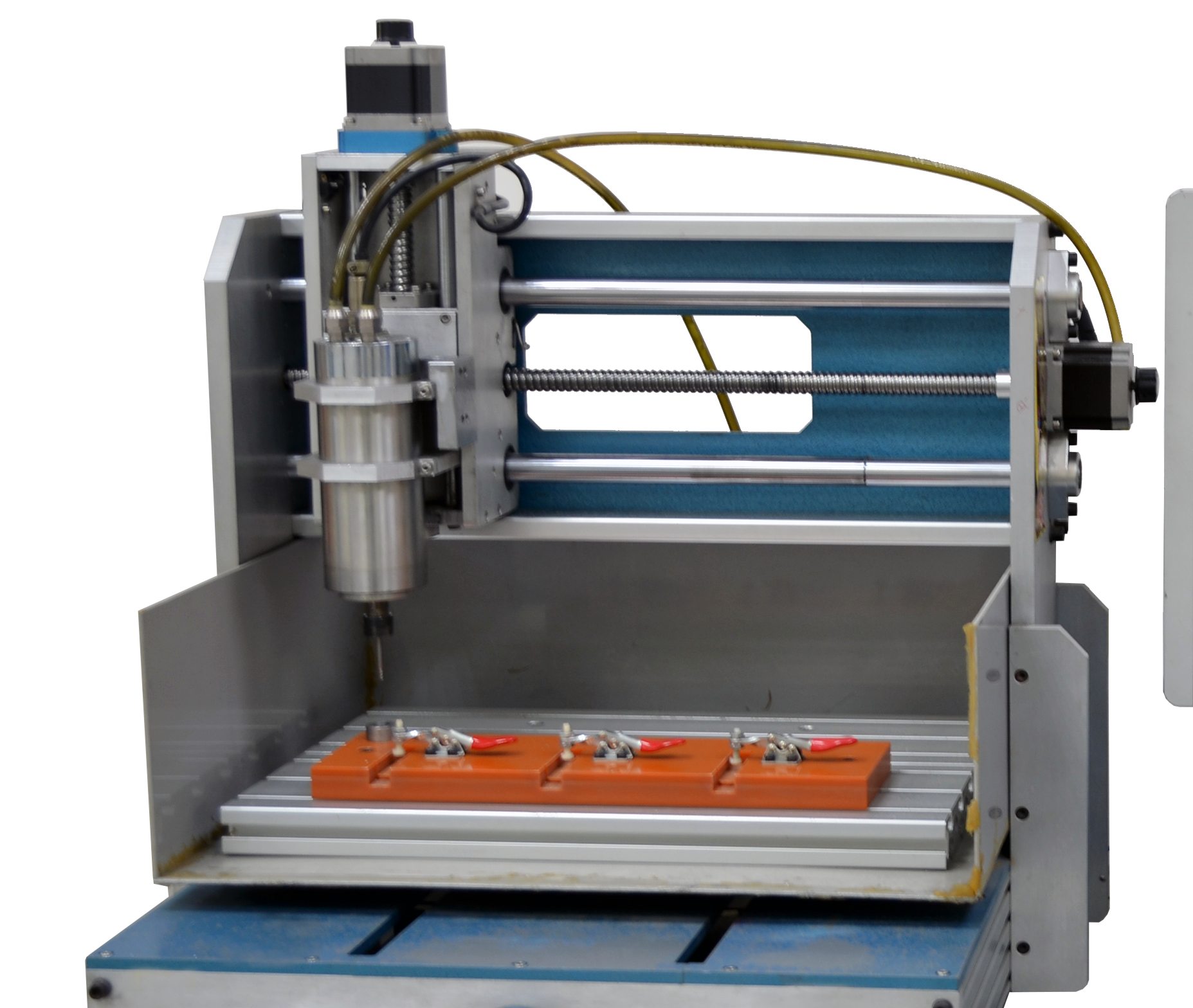

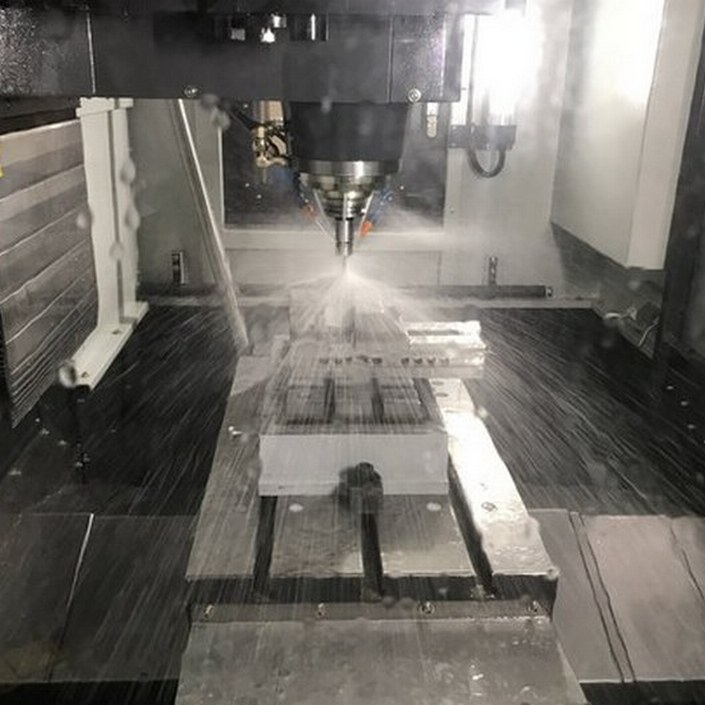

CNC Machining

CNC machining, or Computer Numerical Control machining, is a highly automated manufacturing process that utilizes computerized controls and precision machinery to produce custom-designed parts and components from various materials, including metals, plastics, and composites.

CNC machining can be used on several different material such as metal, wood, plastic, ceramic or composite.

CNC machining is widely used in industries such as aerospace, automotive, medical, electronics, and more due to its accuracy, repeatability, flexibility, efficiency and versatility.